| Specifications | Rated power (kW) | Rated flow rate (m³/h) | Rated head (m) | Voltage (V) | Import size | Price (yuan) |

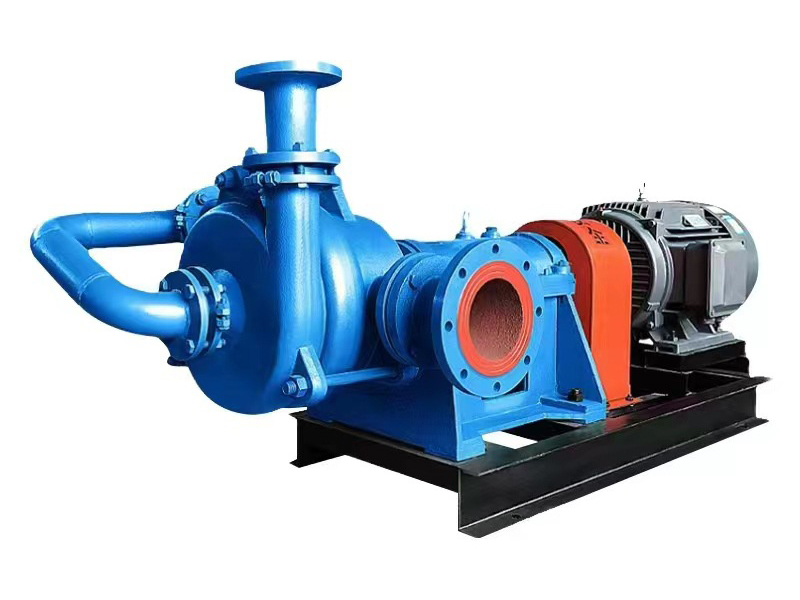

| ZJL slurry pump | 220 | 1100 | 40 | 380 | 1 | 8500 |

| ZJ slurry pump | 500 | 2100 | 100 | 660 | 2 | 6500 |

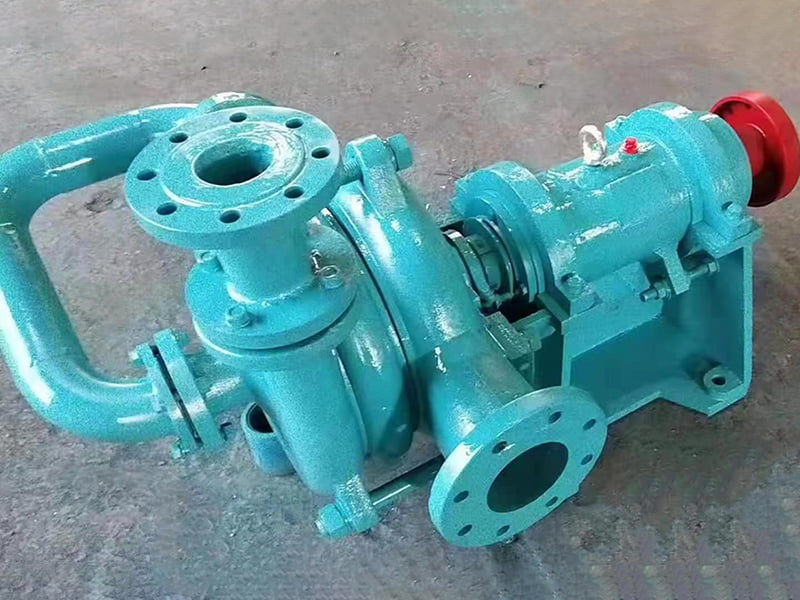

| Fractional slurry pump | 560 | 87.8 | 90 | 1100 | 14 | 2300 |

| Submersible slurry pump | 100 | 288 | 161 | 220 | 5 | 2700 |

| Filter press feed pump | 16 | 90~900 | 8.2 | 110 | 8 | 6700 |

| Brand | Yafei OQLANGAN | Maximum flow | 1800 |

| Maximum head | 110 | Pump body material | High chromium alloy |

| Flange standard | international | Driving method | electric |

Name: Pump, centrifugal pump, single stage pump, mining horizontal submersible fractional slurry pump, filter press feed pump, water pump

Category of pumps: Machinery and industry equipment - pump - centrifugal pump - single stage pump.

Function: Used for pumping, pumping, pumping sand.

Use unit: mine, power plant, steel plant, coal washing plant, sand washing plant, heat company, etc.

Submersible slurry pump is a device used to transport high concentration solid-liquid mixtures, commonly used in mines, construction sites, ports and other places. It has the characteristics of diving operation and can be directly installed in the mud pit for work.

Submersible slurry pumps typically consist of an electric motor, pump body, and hydraulic system. The motor transmits power to the pump body through the hydraulic system, which then pumps the solid-liquid mixture into the pump and delivers it to the designated location through the discharge pipeline.

This pump has excellent anti clogging ability and wear resistance, and can effectively handle high concentration and high viscosity slurry. Meanwhile, diving operations make it flexible and adaptable to various working environments.

Submersible slurry pumps play an important role in industries such as mining, construction, and environmental protection. It can be used for the transportation of diving materials, sludge treatment, tunnel engineering, foundation treatment, and other aspects. By using submersible slurry pumps, work efficiency can be improved, labor costs can be reduced, and environmental pollution can also be reduced.

In summary, submersible slurry pumps are important engineering equipment with advantages such as high efficiency, durability, and flexibility, and are widely used in various fields.

A horizontal fractional slurry pump is a commonly used equipment for transporting mud, coal slurry, and other media with high particle content. Here are several characteristics and advantages of it:

1. Compact structure, occupying small space, suitable for situations with limited space.

2. Low center of gravity, good stability, low vibration and noise during operation, and low requirements for the operating environment.

3. It has self suction ability and can continuously transport media without the need for pre watering, resulting in high work efficiency.

4. There is a certain gap between the rotor and the pump casing, which can transport media containing certain particles and adapt to harsh working environments.

5. With high pressure and the ability to achieve long-distance transportation, it can be widely used in fields such as coal, chemical industry, and mining.

A submerged sand pump is a device used for extracting sand, mud, or solid particles from underwater environments. It is usually widely used in areas such as rivers, lakes, ports, dams, and wetlands that require sediment and silt removal. The underwater sand pump extracts liquid and solid particles together and transports them to other places through pipelines to achieve the goals of cleaning water bodies, maintaining ports, and restoring wetland ecology.

The working principle of an underwater sand pump is to pump sediment into the pump body through the negative pressure effect of the water pump, and then transport it to other places through pipelines. The pump body is usually made of wear-resistant materials to ensure that it is not worn or damaged during long-term use and handling of large amounts of particles.

The underwater sand pump has the following characteristics and advantages:

1. Wide application: The underwater sand pump can be used in various underwater environments, including rivers, lakes, ports, dams, and wetlands.

2. Efficient cleaning: The underwater sand pump can efficiently clean sediment and mud, quickly restoring the smoothness and cleanliness of the water area.

3. Wear resistant and durable: The pump body is made of wear-resistant materials, which can maintain a long service life when dealing with large amounts of particles.

4. Strong flexibility: The underwater sand pump can be adjusted according to specific needs, including adjusting the outlet flow rate, sand pumping depth, and sand pumping speed.

5. Environmental sustainability: By cleaning water bodies and restoring wetland ecology, underwater sand pumps can improve environmental quality and protect ecosystems< P>

In summary, the underwater sand pump is an efficient and suitable equipment for various underwater environments. It achieves water cleanliness and ecological protection by pumping underwater sediment into the pump body and transporting it to other places through pipelines. The underwater sand pump has advantages such as wear resistance, durability, strong flexibility, and environmental sustainability, and is one of the important equipment in the fields of water conservancy engineering and environmental protection.

The feed pump of the filter press is a key component in the filter press equipment. Its main function is to feed the materials to be processed into the filtration area of the filter press, thereby performing solid-liquid separation.

The feed pump of the filter press is usually a centrifugal pump or a plunger pump. A centrifugal pump is a type of pump that generates centrifugal force through rotating blades to transport materials. It has the characteristics of large flow rate and stable pressure, and is suitable for feeding pumps in large filter presses. The plunger pump, on the other hand, is a pump that drives materials through the up and down movement of the plunger. It has the characteristics of high conveying pressure and good stability, and is suitable for feeding pumps in small and medium-sized filter presses

The selection of the feed pump for the filter press needs to consider factors such as material properties, processing capacity, and filtration pressure. For example, for viscous materials, it is necessary to choose a pump that can transport high viscosity materials; For filter presses that handle large amounts of materials, it is necessary to choose a feed pump with high flow rate and efficiency; For situations that require high filtration pressure, it is necessary to choose a feed pump that can provide sufficient pressure.

In addition, the installation and maintenance of the feed pump for the filter press are also important. During installation, it is necessary to ensure that the connection between the pump and the filter press is tight and reliable to avoid water leakage or pressure relief. In terms of maintenance, regularly check the sealing performance and lubrication of the feed pump, and replace worn parts in a timely manner to ensure the normal operation and lifespan of the feed pump.

In summary, the feed pump of the filter press plays a crucial role in the filter press equipment. The correct selection, installation, and maintenance of the feed pump can improve the filtration effect and work efficiency of the filter press, ensuring the normal operation of the equipment.

Welcome to send your message to us